Braided Textiles to improve the competitiveness of Composite MaterialsIndustry in NWE

The COBRACOMP project

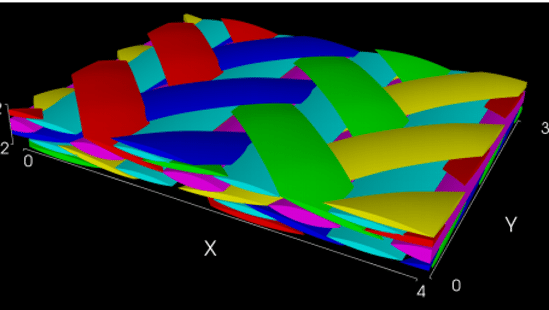

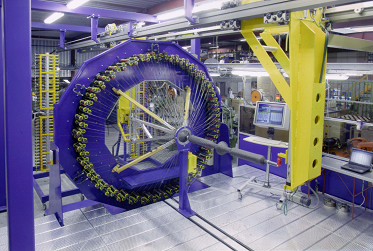

COBRACOMP will focus on the development of a new high performance multilayer triaxial braiding process allowing fast, automated and repeatable manufacturing of composites reinforcements. During the project, two innovative braiding machines will be developed to manufacture two innovative textile braid architectures, as well as digital simulation and part design tools.

The creation of a transnational network on the theme of braided composite materials will help to disseminate information to all project targets. This network will also help sustain the use of project results after its completion

The Benefits of Braiding

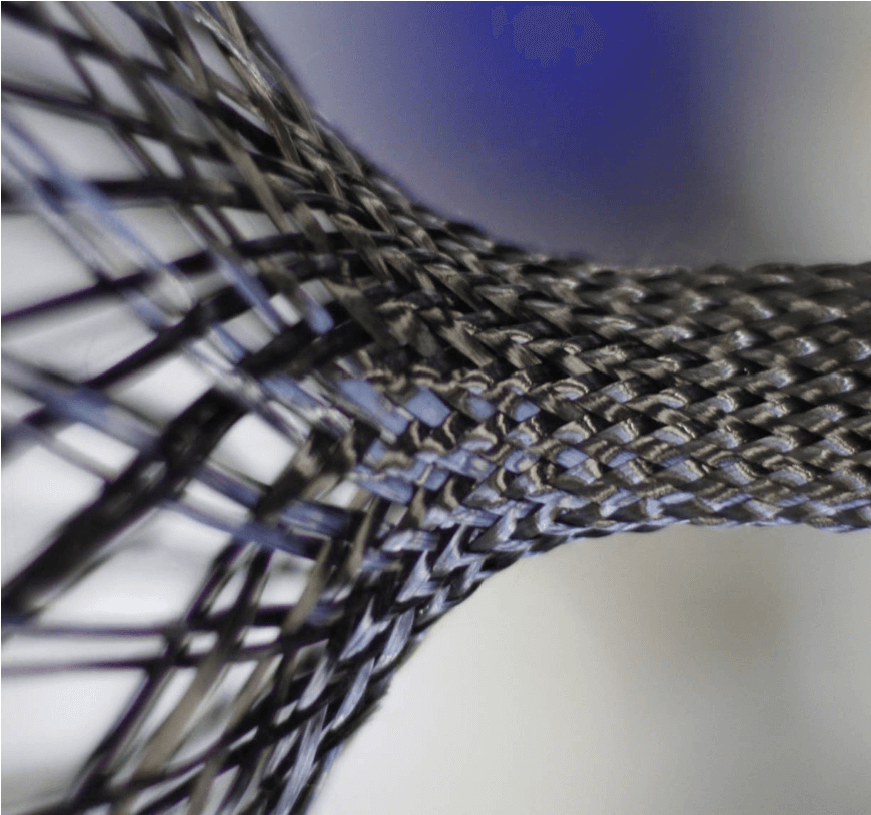

Braiding is a highly automated textile process that allows to manufacture near net shape, preforms, tailored to the shape of complex geometry composite parts.

The new COBRACOMP braid architecture will go beyond standard triaxial braiding with a multilayer assembly with more axial yarn, more fibre fraction, more homogeneity leading to higher mechanical performance.

Main project outputs

- Development of 2 braiding machines to manufacture innovative multilayer 3D triaxial braids

- Manufacturing and testing of composite materials reinforced with the new braided reinforcements

- Demonstration of the technology in relevant conditions with two demonstrators (automotive and aerospace)

- Dissemination of the project results thanks to workshops

- Creation of a new workgroup within a transnational cluster dedicated to braided composites

For more information, visit the Cobracomp website

Our Partners