The tubular carbon fiber braids program is made of high quality carbon fibers and are available off the shelf.

Why should we use braids?

- Braids will take up torsional loads in you component.

- The tubular shape will create no seams and they are easily applied on your product. This will save costs in your manufacturing process.

- The waste rate is verry low as it can be cut to net shape

- Braided architectures provide superior strength and a high damage tolerance

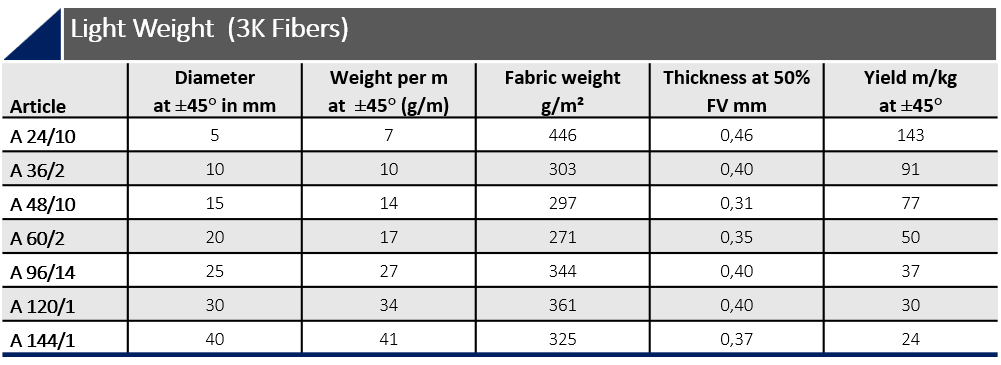

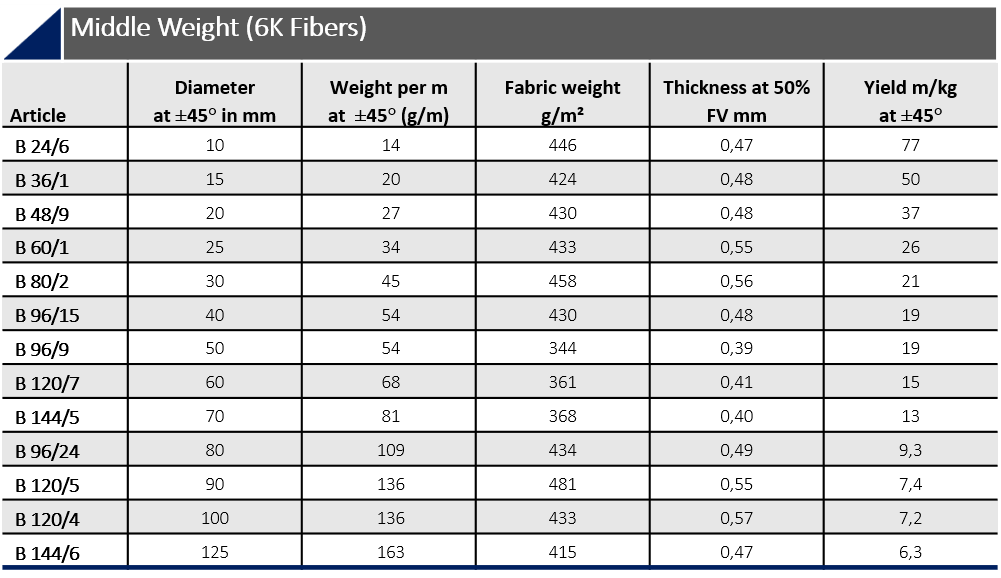

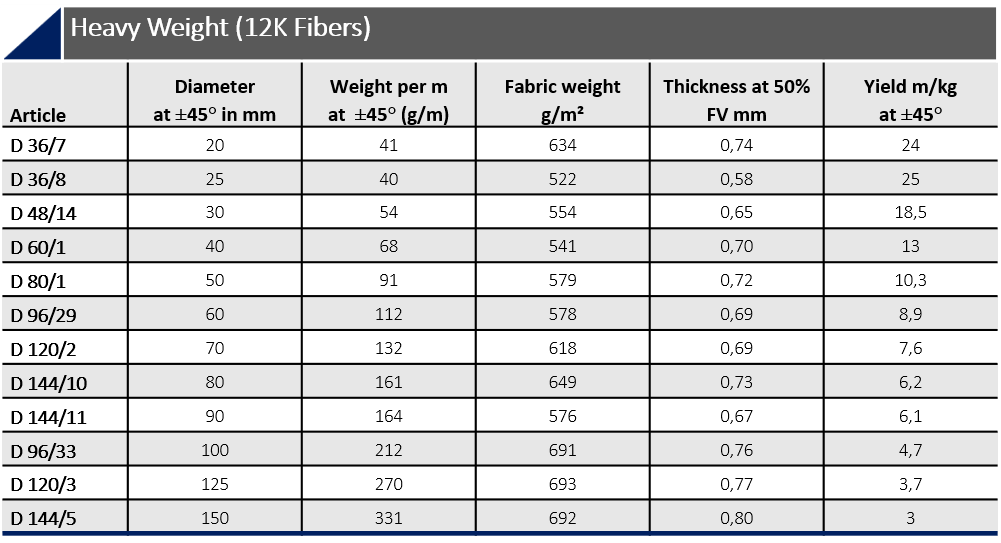

The fiber densities which we are using, are 3K, 6K and 12K fibers.

These fibers create respectively the light (340 g/m2), medium (420 g/m2) and heavy (600 g/m2), braids in our program.

The standard is a good way to start your engineering. Need something dedicated? See our Custom made Section.

Do you need bending as well? Combine our braids with our Carbon Tubular Elastic UD

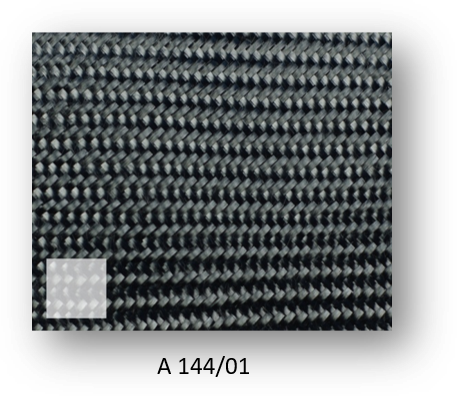

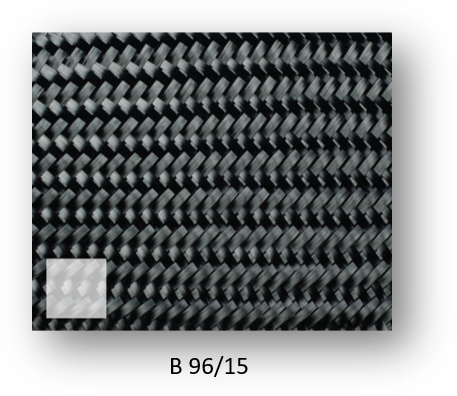

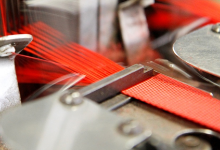

Photo representations of our braids. The cube is 1cm.

Standard Programs

To achieve a higher level of customer service, we have successfully implemented our standard product programmes for many years.

Thermoplastics

Besides our selection of standard programs, Eurocarbon produces a large variety of tailor made constructions.

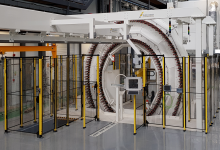

Overbraiding & equipment

Overbraiding is the technique used to produce net shape cost-effective structural preforms.

Custom made

We provide custom / tailor made solutions for our customers. Check the basic information required for a product proposal.