Affordability The primary drive for low cost lightweight composite structures has resulted in a number of new technologies with potential for automation. For thermoset materials, low cost fabrication can be achieved with automated preform fabrication, such as braiding and automated tow placement, followed by one of various resin injection techniques. Low cost fabrication of thermoplastic components can be achieved by press forming and by fibre placement with in-situ consolidation. Other processes may require the use of an autoclave. ACM-TC and its partners provide the expertise and facilities for all of these techniques.

The primary drive for low cost lightweight composite structures has resulted in a number of new technologies with potential for automation. For thermoset materials, low cost fabrication can be achieved with automated preform fabrication, such as braiding and automated tow placement, followed by one of various resin injection techniques. Low cost fabrication of thermoplastic components can be achieved by press forming and by fibre placement with in-situ consolidation. Other processes may require the use of an autoclave. ACM-TC and its partners provide the expertise and facilities for all of these techniques.

Facilities of ACM-TC

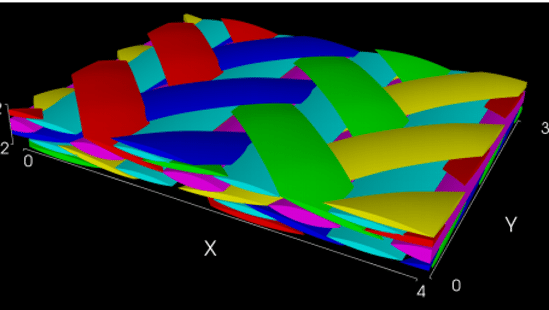

The core of ACM-TC is the R&D facility for composites manufacturing at NLR. With the financial support of the provincial government, an automated fibre placement machine was procured from Automated Dynamics (ADC), which arrived at NLR in 2005. The strong endorsement of a number of industrial members was crucial for this procurement. Other equipment consists of an automated RTM-machine with full process monitoring and control features, an autoclave, a C-scan, and clean rooms and a well-equipped testhouse to perform material qualification and structural certification programmes. Beside the facilities at NLR ACM-TC partners each bring in their specific facilities such as braiding machines at Eurocarbon and fundamental reasearch facilities at the universities of Delft and Twente.

Contracts and projects

ACM-TC carries out R&D projects together with industries with a specific need. A consortium is formed, and a joint research proposal is formulated and propose for funding. The industry has full access to the facilities where the developments are taking place. With in-house funding or with funding acquired singularly, partners of ACM-TC also carry out independent research projects, aimed at extending the capabilities of ACM-TC, or to explore novel technologies. Participation in EU-projects is also pursued. Workshops are organised twice a year for all participants, to present non-confidential project results, to stimulate discussions, to define new research topics and to develop new opportunities.

Activities within ACM-TC![]() Within the ACM Technology Centre the following type of activities are carried out:

Within the ACM Technology Centre the following type of activities are carried out:

- Research and Development

- Basic research towards novel technologies for automated composites manufacturing

- Feasibility and trade-off studies for specific applications

- Technology demonstrations at component level

- Concept development and prototyping for automated fabrication of composite structures

- Small series production

- European demonstration centre for ADC’s automated fibre placement equipment

- Education via courses and student projects

- Support for “the region” and for “small and medium enterprises”

Industrial members and their products

| Partner | Expertise |

| Ten Cate | Advanced Composites Thermoplastic materials |

| Stork Fokker AESP | Aero-Structures |

| Stork SP Aerospace B.V. | Landing gears |

| Dutch Space | Space Structures |

| Eurocarbon B.V. | Braiding technology |

| Airborne International | Composite structures |

| Futura | Filament wound structures |

| SKF Dutch Skil B.V. | Offshore, Windturbine Technology |